Today, I was able to perform the first full test of the crusher on my bot. I did not go well.

Two separate issues were encountered during testing. The first one is my fault, the second one is only probably my fault.

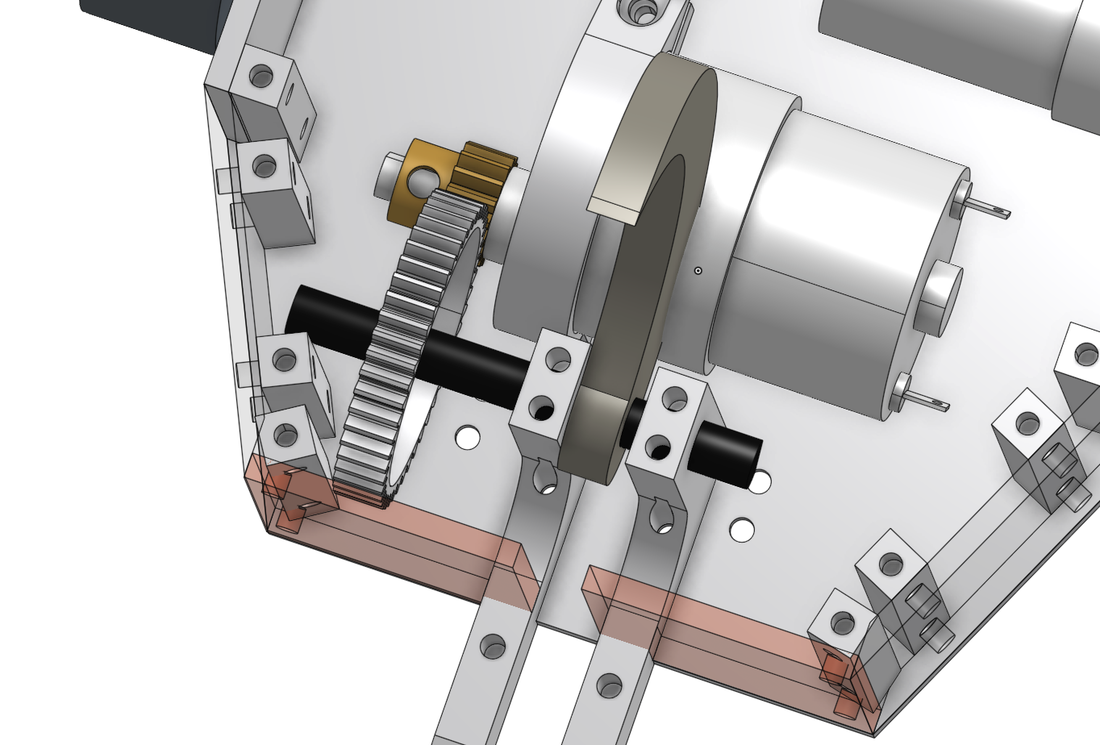

Firstly, I underestimated (more like failed to estimate) how much force there would be trying to separate the final stage gears of my crusher. At some point I changed my design to make the front forks, and the shaft columns one piece. When I did this I moved the columns closer to the center line of bot, leaving the gear cantilevered at the end of the shaft.

Firstly, I underestimated (more like failed to estimate) how much force there would be trying to separate the final stage gears of my crusher. At some point I changed my design to make the front forks, and the shaft columns one piece. When I did this I moved the columns closer to the center line of bot, leaving the gear cantilevered at the end of the shaft.

The gears are now pulling apart and slipping. The gears have a pressure angle of 20 degrees, and as it turns out there is almost 120 lbf trying to push them apart. Somehow, I will have to reinforce the end of the shaft.

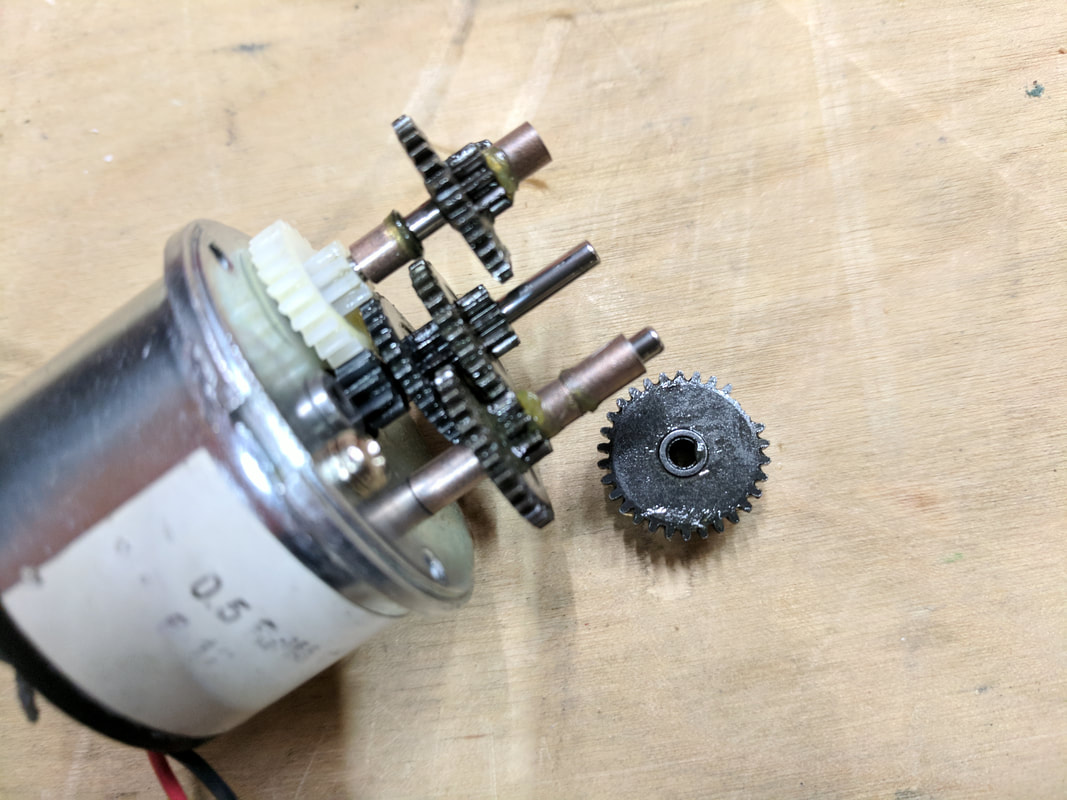

The second problem I encountered is that the gear-motor I purchased is not capable of producing its advertised torque. Instead if you stall the output shaft and continue to run the motor, you will blow teeth inside of the gear box. I've now been able to reproduce this twice. It may be due to the end of the motor shaft being unsupported, but after seeing the tiny size of the gears inside the gearbox I suspect it is simply under engineered.

The second problem I encountered is that the gear-motor I purchased is not capable of producing its advertised torque. Instead if you stall the output shaft and continue to run the motor, you will blow teeth inside of the gear box. I've now been able to reproduce this twice. It may be due to the end of the motor shaft being unsupported, but after seeing the tiny size of the gears inside the gearbox I suspect it is simply under engineered.

Luckily, I purchased a pair of these gear-motors and as each gear stage inside the motors is identical, I can swap gears between the gearboxes to get a functioning set. For now I'm simply limiting the current I'll send the motor until this issue can be resolved.

RSS Feed

RSS Feed